Our Production

About Biederlack

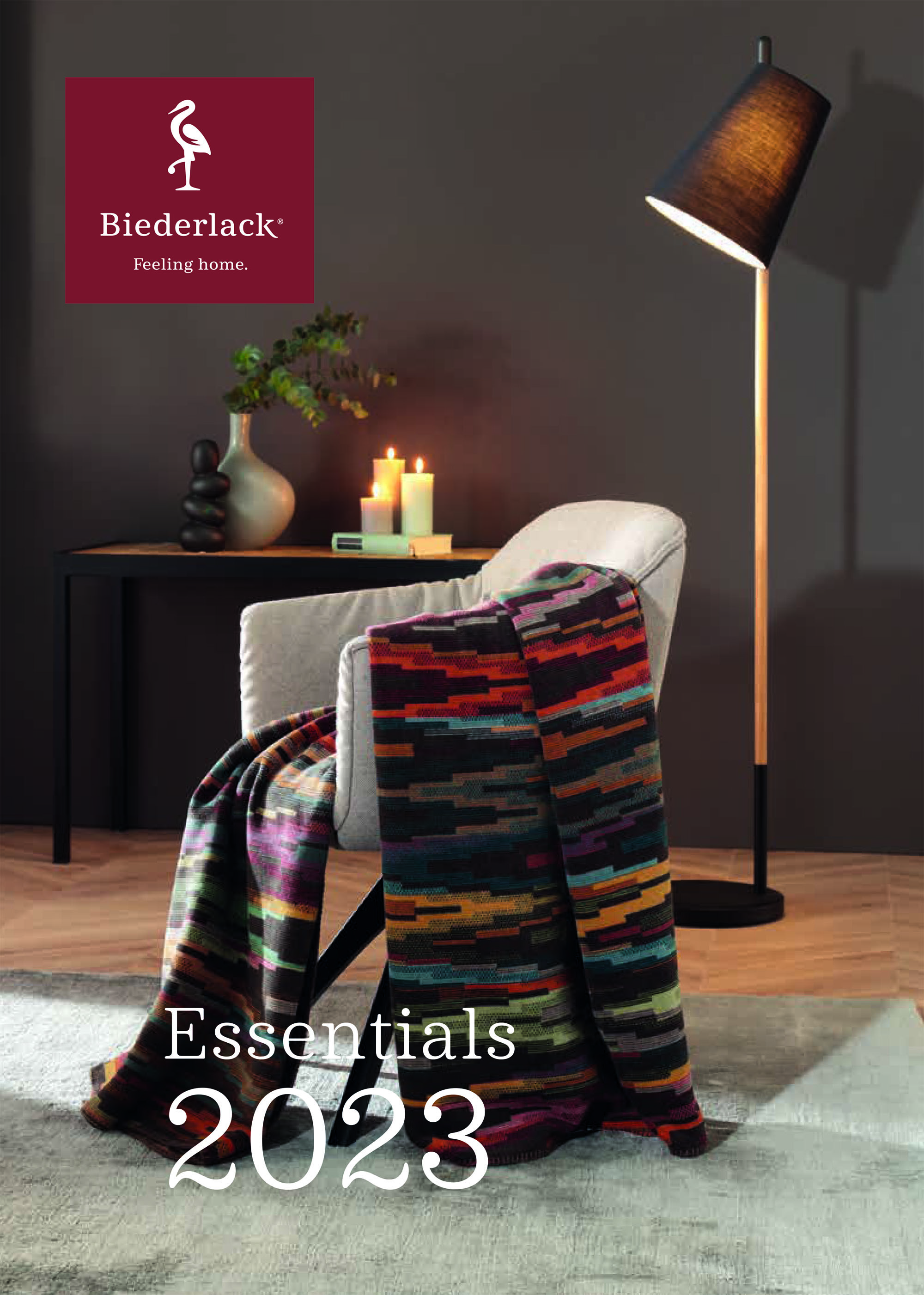

Feeling home – our products guarantee you this feeling. High-quality snuggle blankets, plaids and cushions make your home an even better place – even more snuggly and comfortable.

By combining quality, design and functionality, we have been setting standards for more than 130 years and turn every single one of our blankets into a favourite piece thanks to our passion, knack for creativity and a sprinkle of curiosity. Our quality standards are deeply rooted in our history. We work hard every day to offer our customers quality at affordable prices by optimising our entire value chain, building long-term relationships with our suppliers and investing in our fully integrated production process in Greven (Germany).

Feeling good is another important component of our company culture: we produce in a sustainable and responsible manner by protecting people, the environment and valuable resources.

“Our passion creates that wonderful feeling – the feeling of being at home.” - Lotty Biederlack

Our Production in Greven

Made in Germany